DB mindbox is excited to run its Future of Operations & Maintenance (FOM) 2026 program! Together with our strong partner DB InfraGO, we are looking for exciting startup solutions for various use cases. DB InfraGO is the rail infrastructure company of Deutsche Bahn Group, responsible for operating, maintaining, and expanding Europe’s largest rail network. Its duties include providing high-quality infrastructure for railway undertakings, managing over 33,000 km of track, operating around 5,400 stations, and producing timetables.

This 100-day program gives startups the chance to customize and live-test their solution to real challenges that DB is facing. Selected teams will enter a 100-day Proof of Concept (PoC) with DB to further develop and test their solution.

What’s in for you?

- Exclusive access to DB experts, data and networking opportunities

- Prize money of 10.000€ (up to 25.000€ in total, depending on the specific requirements of the use case)

- Professional coaching sessions – including pitch preparation before the Selection Day, individual sessions during the PoC, and presentation training ahead of the Day-100 Final Event

- 24/7 access to our coworking space at our loving office site at Berlin Jannowitzbrücke

- You will be supported by a dedicated DB mindbox startup manager

This is a great opportunity to lay the foundation for joint projects and successful long-term collaboration with Deutsche Bahn Group, Europe’s largest mobility and infrastructure provider.

You have questions about the program?Check out our FAQs or send an e-mail to the program manager Viviane Elhaus dbmindbox@deutschebahn.com. Furthermore, you can join our weekly open Q&A session every Tuesday from 12.15 – 1 pm Berlin time here. We look forward to answering all your questions!

01 – Innovative Approaches for Slag Collection and Prevention

During rail grinding, so-called slag is generated – metallic residues from the rails that accumulate on scrapers, cool down, and harden into lumps weighing up to 10 kg. These lumps fall uncontrolled onto the track and must be laboriously removed at the end of each shift. On average, around 200 kg of slag accumulates per shift along several kilometers of grinding track. Today, this material is collected manually by two employees per shift – a process that is time-consuming, physically strenuous, and increasingly unattractive given the shortage of skilled labor. We are therefore seeking technical solutions that can replace or significantly reduce manual slag collection. The objective is clear: lower workforce requirements, reduce physical strain on employees, and at the same time improve efficiency, quality, and overall safety while cutting costs.

02 – Smart Capacity Management for Service Facilities

Train operating companies use DB InfraGO’s Anlagenportal Netz (APN) to book tracks in service facilities across Germany. These facilities serve as parking areas for trains, wagons, and locomotives and are used by both passenger and freight operators. Depending on the location, tracks differ in length, layout, and available equipment such as power supply, water points, or toilet servicing. Today, however, booked capacity cannot be cancelled or released digitally. Once a storage siding is contracted, it remains reserved around the clock for the entire contract period — even if the customer only needs it intermittently. This leads to limited transparency: to other users, most facilities appear fully booked at all times.

If customers wish to free up capacity for certain hours, days, or longer periods, this is only possible through a manual and non-transparent “secondary use” process (Nebennutzung), where regional teams must contact the main user to check availability. There is no way for other operators to see free capacity proactively. With rising demand and a highly constrained infrastructure, DB InfraGO is looking for digital solutions to make capacity management smarter. The goal: enable customers to independently release unused capacity and make these time windows visible for secondary use — allowing other operators to request and book them.

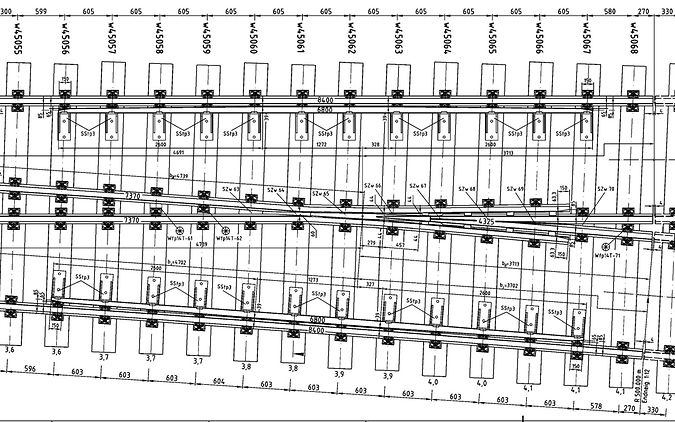

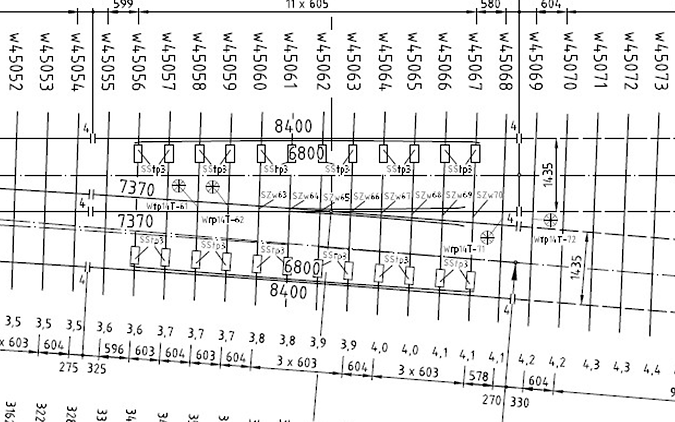

03 – Create Bills of Materials Automatically from Installation Plans

Every switch in the DB InfraGO production process is unique – with individual geometries, components, and fastenings. Depending on the installation situation, wooden, plastic, or concrete sleepers are used, and each individual sleeper in the switch area is manufactured individually. Today, the bill of materials – i.e., the list of all required sleepers and materials – is still derived manually from installation plans based on a standardized, drawn plan showing the switch position including the sleepers to be used. This process is time-consuming and prone to errors: even one incorrectly ordered sleeper can lead to delays on the construction site.

We are looking for digital solutions that automatically identify the required sleepers from the installation plans and transfer them to a parts list. The aim is to reduce manual checking and transfer work and minimize errors in the current manual process. Of particular interest are approaches based on computer vision, object detection, or OCR+, for example, which can recognize graphic elements, text, and deviations in technical drawings. These systems should independently identify different types of sleepers and special characteristics and derive a digital material list from this information.

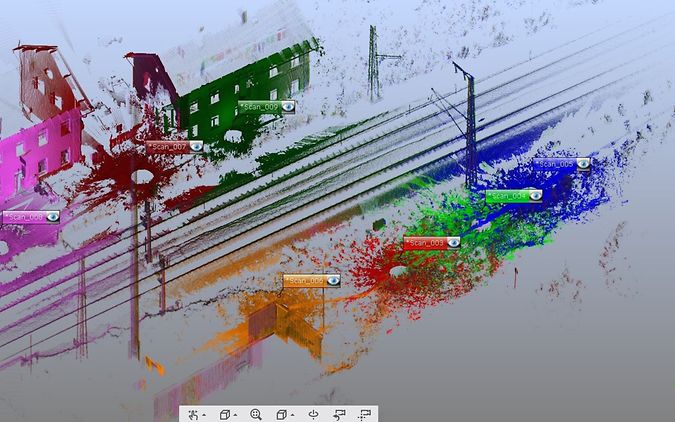

04 – Collaborative BIM Models with Measurements

In modern construction projects, efficiency and accuracy are crucial for staying on schedule and within budget. Yet, the use of BIM models in everyday work has some hurdles – some essential processes are still time-consuming, error-prone, and fragmented. At DB InfraGO, BIM models are used in the planning phase of construction projects and it is often difficult to obtain key information, such as measurements, from the BIM model during the construction phase. By leveraging BIM more effectively we can accelerate planning, reduce manual work, and create a seamless digital workflow. We are looking for innovative solutions that enable faster, more accurate, and more collaborative construction processes. If you want more information about the use case, simply click on the tiles.

Timeline

07.12.2025 – Application deadline

Last day to apply for the program (eob.)

19.12.2025 – Announcement of candidates

Invitation of selected teams is expected to take place an December 19, 2025

27.01 2026 – Selection day

Pitch your solution live on stage to a jury and audience in Berlin. The Selection Day is held on January 27, 2026.

23.02.2026 – Start of program

The program starts with an onboarding week where you'll get to know DB mindbox and the department of DB InfraGO behind your use case. Together, you'll define your goals and officially kick off the 100-day project.

Beginning of June – End of program

End of 100 day Proof-of-Concept (PoC) and presentation of results is expected to take place in early June 2026.